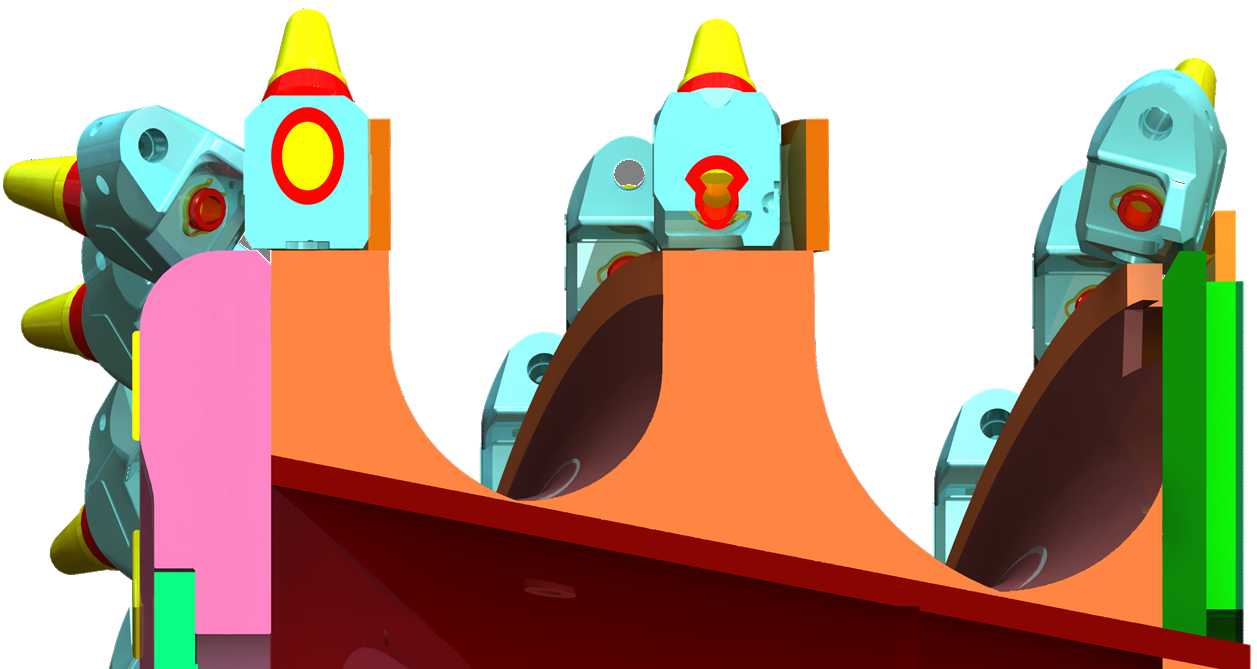

The Globoid drum in combination with the EB-water spray system sets new standards in efficiency, durability, safety and dust reduction.

The output and the haulage speed are mainly limited by the loading ability of the shearer drum, provided that there is enough machine power. To increase the ouput KRUMMENAUER developed the patented Globoid shearer drum. Computer calculated cutting tracks are fitted to the individual needs taking mineral and shearer loader specifications into account. The loading behavior is adjusted directly to the volume needed. This decreases coal crushing as a result of wild tumbling and thereby reduces dust formation and machine power consumption.

The prototype of the Globoid shearer drum was tested under real conditions in the mine Reden. Compared to a cylinder drum the following advantages had been found out (extract):

- Optimized loading abilities

- Increase in machine marching speed

- Improved repair abilities

- Advanced graining structure:

- Decrease of fine coal (grain size < 10mm) at 19%

- Drecrease of coaldust (grain size < 0,5mm) at 40%

- Increase of lump coal (grain size > 50mm) at 75%

- Strong construction

- Reduction in power demand of machine

Globoid shearer drum |

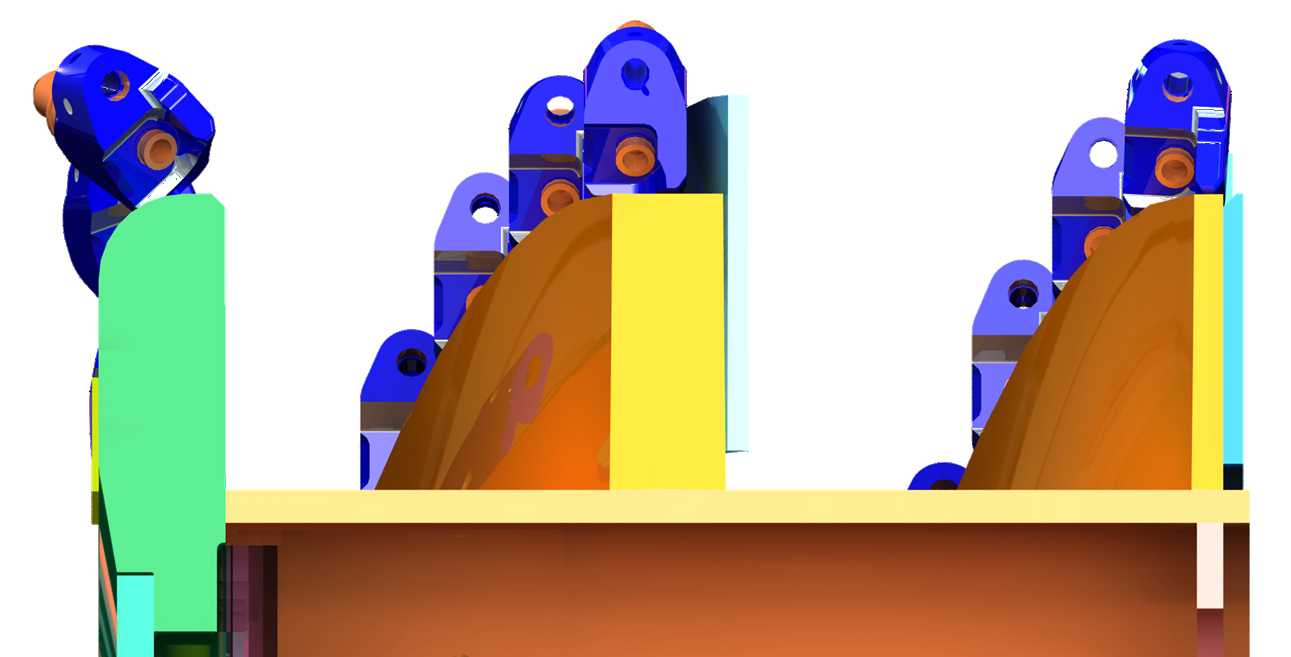

Cylinder shearer drum |

|

|

|

The complete test report of the KRUMMENAUER Globoid shearer drum can be downloaded here. The daily underground operations confirm the advantages of the Globoid shearer drums. This new development made KRUMMENAUER the market leader of shearer drums in Germany. Today Globoid drums are increasingly used in mining in numerous countries worldwide.